GLASS MANUFACTURING TECHNOLOGY: LATEST TRENDS AND METHODS

Glass is a unique material that we use every day in our lives, but few people think about how it is produced. Modern glass-making technologies have become more sophisticated and precise, allowing for stronger, more durable, and more beautiful products. In this article, we take a look at the latest trends and techniques in glass making.

There are two main methods of glass production: melting technology and vacuum melting technology.

The vacuum melting technology is used to produce high-quality optical glass that is used in instruments, telescopes, cameras, and other devices that require high transparency and strength. In this method, the glass is heated in a vacuum furnace to a temperature sufficient for melting and then cooled to create a specific shape.

The melting technology, or melting method, is used to create ordinary glass that we see in everyday life. In this method, glass is created by melting a mixture of silicates and other components at high temperature. Then the glass is formed into the desired shape and cooled.

Latest trends in glass manufacturing technology

In recent years, glass manufacturing technology has reached new heights. Modern methods allow for the creation of glass with more precise dimensions, more durable and long-lasting. Some of the latest technological achievements include:

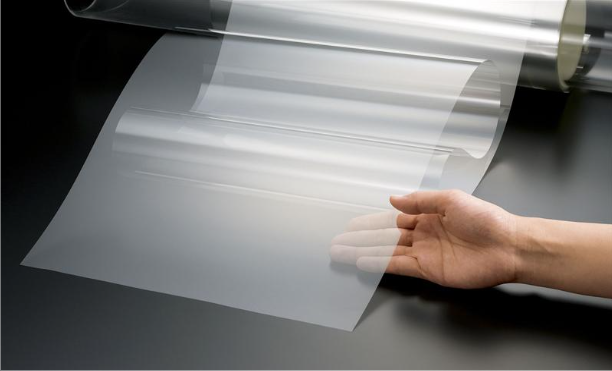

Thin glass

Thin glass is the latest trend in glass production, allowing for the creation of very thin sheets. This type of glass is often used to create smartphones, tablets, and other electronic devices. Thin glass is stronger than ordinary glass and has a higher degree of transparency.

Chemically tempered glass

Chemically tempered glass is one of the most common types of strengthened glass. This glass is obtained by tempering ordinary glass using a chemical process. Chemically tempered glass is stronger, impact-resistant, and better resists thermal expansion, making it ideal for use in doors, windows, and glass partitions.

Ultra-thin glass

Ultra-thin glass is a type of glass that is even thinner than thin glass. It has a thickness of 0.1 to 0.4 mm and can be used to create very thin and lightweight devices such as smartwatches, glasses, and other electronic devices. Ultra-thin glass has a high degree of strength, transparency, and scratch resistance.

Automated manufacturing

Automated manufacturing is also a part of modern glass technology, which significantly increases the production speed and reduces the amount of waste. Automated production lines are equipped with sensors and cameras that monitor the quality of each part of the manufacturing process

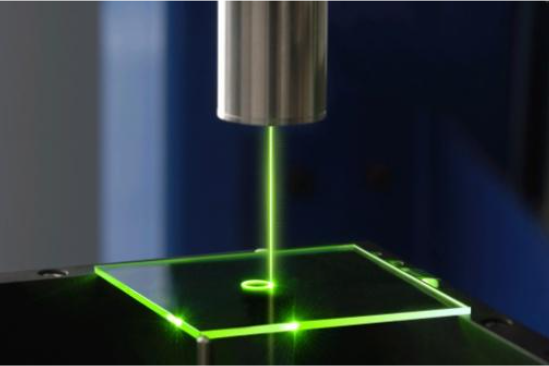

Glass laser processing

Glass laser processing is a new technology that allows creating different designs and patterns on glass. Glass laser processing can be used to create unique glass doors, partitions, and other products.

Nanotechnology

Nanotechnology is the latest trend in glass production, which allows creating glass with various properties. For example, nanotechnology can be used to create glass that changes its color depending on the viewing angle or to create self-cleaning glass.

In conclusion, modern glass manufacturing technologies are becoming more precise and innovative. New manufacturing methods allow creating stronger, more durable, and higher-quality glass that meets the needs of our time. In their work, glass companies must keep up with new trends in glass manufacturing technologies to be at the forefront of the industry and offer their customers the most advanced solutions.

Although glass is one of the most common materials in the world, its manufacturing technologies are constantly improving. The rapid development of new glass manufacturing methods leads to the possibility of creating unique and innovative glass products that could not be realized before. New technologies in glass production open a wide range of opportunities for designers and architects, who can create unique products that meet the needs of the modern world.

In the end, glass manufacturing technologies continue to evolve and improve. New manufacturing methods allow creating stronger, more durable, and higher-quality glass that meets the needs of our time. Glass manufacturing companies are required to keep up with new trends in technologies to be at the forefront of the industry and offer their customers the most advanced solutions. Ultimately, this will help create more high-quality and durable glass products that meet the needs of the modern world.

OUR CONTACTS

- (347)860-7999

- sales@glass-desire.com

- 1951 68th street, Brooklyn NY 11204

- 9:00AM - 6:00PM | Monday - Friday